Repairing Worn Rudder Post Tubes

From the builder:

After years of use, the rudder tube on some boats may become worn and somewhat sloppy and allow movement of the rudder post in the tube. When the post cap can be seen to be moving slightly (1/8" or more), this is evidence that the tube may be worn.

A slightly worn rudder tube does not present a safety or structural problem but can be annoying when attempting to concentrate on steering to weather.

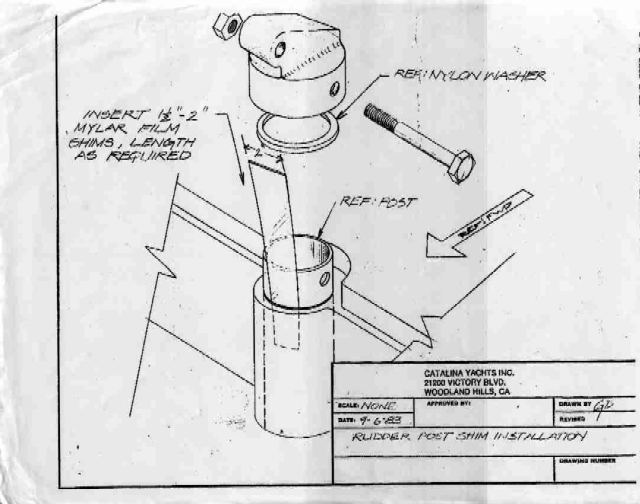

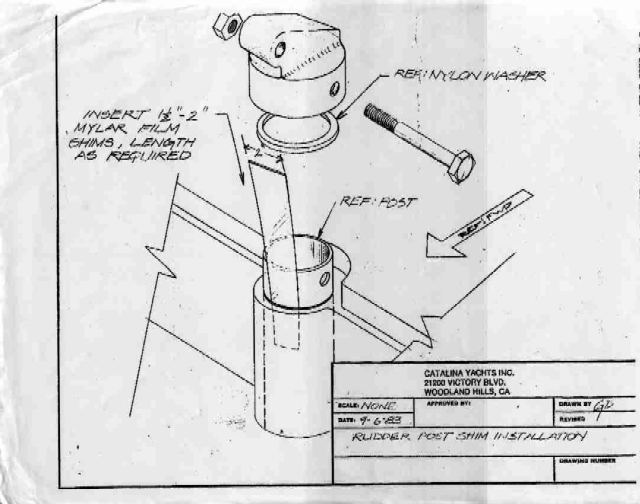

Two methods can be used to correct a worn rudder tube. The first step is to fill the tube around the post using mylar drafting film.

Caution:

If the boat is in the water,

support the rudder from below with a net or ropes before removing the top cap

of the rudder! Otherwise the rudder will drop from the boat!

Stock drafting film of .002 or .005 thick is available at most drafting supply shops.

Insert the film as illustrated, working the film strips as far down into the tube as possible. It is recommended that the tube be rinsed with fresh water to clear it of any sand or dirt particles out of the tube before inserting the shims.

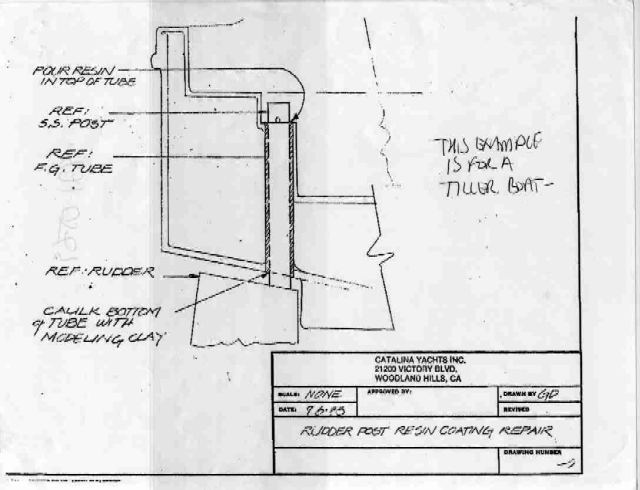

The second recommended method for restoring a worn tube is to cast resin around the post inside the tube to build up the inside walls of the tube.

This must be done with care to insure adhesion of the resin to the inside of the tube.

Proceed as follows:

1) Remove the rudder, take off the post cap, and pull the rudder out through the bottom.

2) Clean out the inside of the tube using acetone with a rag, rinse several times to remove all

grease or lubricant.

3) Sand the inside of the tube using a drum sander on an extension in an electric drill motor or

sandpaper on a mop handle

4) Wipe the inside of the tube clean.

5) Wax the rudder post with "honey wax" or mold release wax.

6) Reinstall the rudder in the hull. Fix the rudder in place using a bolt or wooden dowel

through the hole in the post. Do not install the rudder post cap at this time.

7) Caulk the post where it exits the hull with modeling clay to seal any gap between the

post and the tube.

8) Mask around the tube at the top exposing only the gap between the post and the tube.

Mix and pour polyester or epoxy resin and fill the gap between the post and the tube until

the gap is filled. Retain a little resin in the mixing pot for observation. When the resin

is in the semi-hard "gelled" stage, move the rudder gently from side to side - to break

any bond between the post and resin - and to form the resin to accommodate any

irregularities in the post.

9) After the resin is fully cured, remove the modeling clay, push the rudder up into position,

and install the post cap.

After shimming or recoating the rudder tube, lubricate the tube with Teflon or silicone. Bearing grease or other sticky lubricants are not recommended. They entrap sand and dirt particles and cause the tube to wear.

Keep the tiller tied off when not using the boat to minimize unnecessary wear on the rudder assembly.